Roar Simulation was busy at ProMat in April. Not only were we talking to prospects about AutoMod, but we spent a lot of time on the show floor seeing what is new in material handling. ProMat 2019 showcased many new automation and material handling technologies:

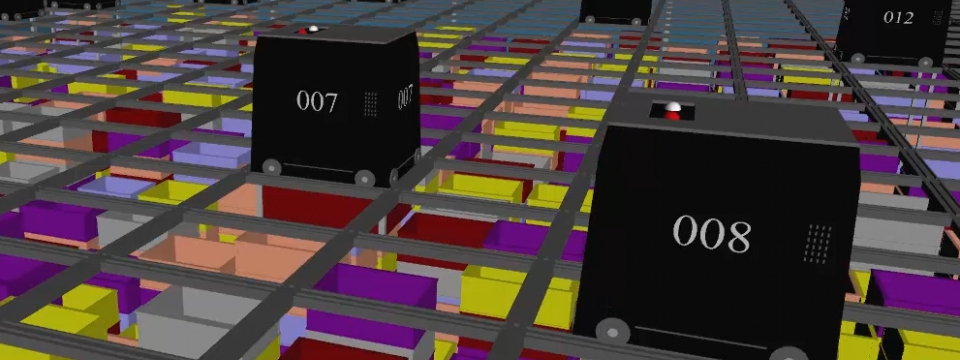

- Cube storage systems like AutoStore

- Autonomous mobile robots (AMR)

- Case handling shuttle systems

- Robotic item picking

- Warehouse control and management software

Not only can these new automation technologies be expensive, implementing them can be disruptive to your current operations. Most warehouse operations professionals have to work within the constraints of their existing facility, and don’t often get to design a new greenfield facility. You have to keep meeting your numbers, surviving through peak periods, day by day and week by week. Adopting automation can be risky, but how can you reduce that risk?

Simulation modeling and analysis can help. Using simulation technology, engineers can create a “Digital Twin” of your existing operations. Then you can test drive new technology in the simulation and perform “what if” scenarios to see how the new technology might work in six months or six years as your business expands. Distribution and order fulfillment centers are complex, dynamic facilities with many moving parts. Simulation can provide unparalleled insight into how new automation might help, or not.

Taking a holistic, “full facility” approach to simulation takes time and effort, as I stated in my last blog post. But the potential insight is worth the effort, especially if a company can continue to use their “Digital Twin” to answer operational questions. In two years, when ProMat comes back to Chicago, there will likely be more new technologies with big promises. Will you be ready in 2021 to thoroughly evaluate how automation could help your business?

If you are interested in learning how you can test drive automation technology, please let us know.